ISO 12944-1 & 2 - Corrosion Protection for Steel Structure

Introduction

Steel structures are widely used in various industries, but unprotected steel is highly susceptible to corrosion when exposed to atmospheric conditions, water, or soil. Corrosion can lead to severe damage, impacting the durability and functionality of the structure. To prevent this, steel structures require proper protective measures.

The ISO 12944 series provides comprehensive guidelines for corrosion protection using paint systems, covering all critical aspects necessary for achieving long-term durability.

Key Terms in Corrosion Protection

- Substrate: The surface to which the coating material is applied.

- Corrosion: A process where metal reacts with its surroundings, causing it to change and weaken. This can damage the metal itself, the environment, or the equipment it is part of.

- Paint: A pigmented coating that forms a protective film on a substrate, providing both decorative and functional benefits.

Durability of Coating Systems

ISO 12944 defines durability in four categories based on expected performance until the first major maintenance is required:

- Low (L): Up to 7 years

- Medium (M): 7 to 15 years

- High (H): 15 to 25 years

- Very High (VH): More than 25 years

Important: Durability is not a guarantee period. It is a technical planning parameter to help owners set up a maintenance program.

The selection of a coating system depends on two main factors:

- Type of environmental conditions the structure will be exposed to.

- Required durability to ensure long-term protection.

Note: ISO 12944 applies to carbon steel structures (≥3 mm thickness) designed using approved strength calculations.

Classification of Environments & Corrosivity

Corrosivity refers to the ability of an environment to cause metal corrosion. One of the most significant factors affecting corrosion is atmospheric corrosion, which occurs when moisture forms a thin film on the metal surface.

Factors that accelerate corrosion:

- High relative humidity

- Condensation (surface temperature at or below dew point)

- Pollution & corrosive pollutants

Atmospheric Corrosion Categories

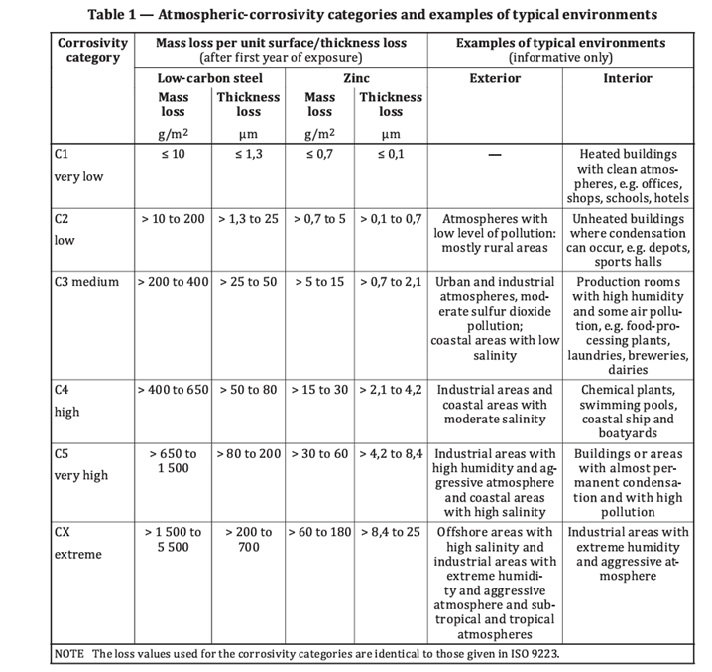

Based on ISO 9223, atmospheric environments are classified into six corrosion categories. Understanding these categories is crucial for designing and testing the durability of protective coatings.

Figure 1: Atmospheric corrosivity categories and typical mass loss.

Figure 1: Atmospheric corrosivity categories and typical mass loss.

The corrosivity categories are defined by the amount of metal loss (in microns or mass) over one year of exposure:

- CX (Extreme): 200–700 microns loss (Extreme industrial/offshore areas)

- C5 (Very High): 80–200 microns loss (Industrial/coastal with high salinity)

- C4 (High): 50–80 microns loss (Industrial/coastal)

- C3 (Medium): 25–50 microns loss (Urban/Industrial)

- C2 (Low): (Rural areas)

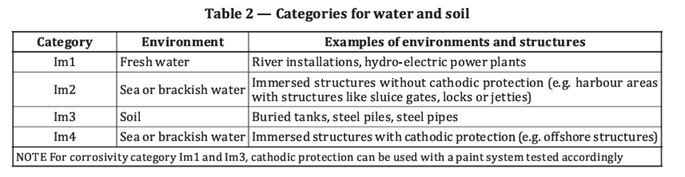

Categories for Water and Soil

For structures immersed in water or buried in soil, specific categories apply.

Figure 2: Corrosivity categories for water and soil environments.

Figure 2: Corrosivity categories for water and soil environments.